XLPOWER

XL70V2C14-Canopy

XL70V2C14-Canopy

Couldn't load pickup availability

Specter 700v2 ultimate Canopy *1

Canopy grommet *2

Fit for Specter 700v2 ultimate

Share

TECHNICAL SPECIFICATIONS

Length w/o main blades: 1,383 mm

Overall height: 351 mm

Frame width: 217mm

Weight (RTF): approx. 5,400 g

Main blade length: 685 – 720 mm

Tail blade length: 105 – 115 mm

Main shaft diameter: 15 mm

Feathering shaft diameter: 10 mm

Tail boom diameter: 32 mm

Tail ratio: 4.76 : 1(5.0Optional)

Drive system: Belt-driven tail, helical main gear

Gear ratio: 9.63 : 1(8.15-11.77 Optional)

Motor mount: One-piece reinforced CNC aluminum design

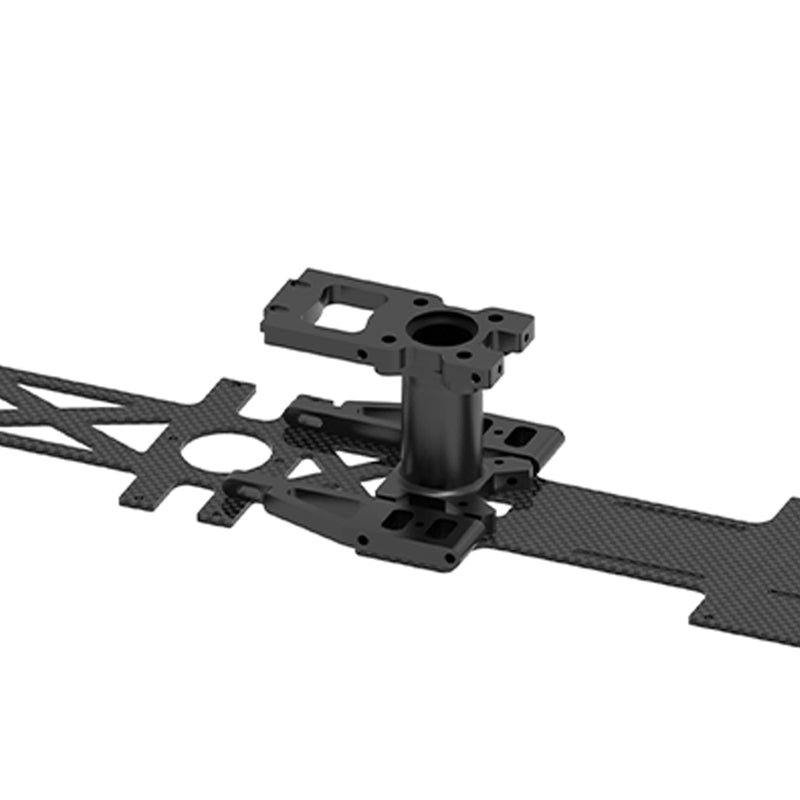

Frame structure: Multi-layer carbon fiber with strengthened center section

Swashplate geometry: 120° CCPM, 1:1 control ratio

Power system: 12S Li-Po (recommended)

ESC rating: 130 – 260 A class

Motor class: 4525 / 4530 size

Head & tail material: 7075-T6 aluminum

Gyro mount: Rear-mounted vibration-isolated platform

Battery tray: Quick-release latch system

The Heart of

ULTIMATE CONTROL

The Specter 700 V2 Ultimate rotor head represents the pinnacle of precision engineering and flight refinement.

Each component is fully CNC-machined from 7075-T6 aerospace-grade aluminum in a single setup,ensuring exceptional accuracy, rigidity, and near-zero tolerance deviation.

This advanced design delivers unmatched stiffness, perfect tracking, and ultra-smooth control response,even under the extreme dynamic loads of modern 3D flight.

The 1:1 swash-to-rotor geometry guarantees completely linear cyclic and collective behavior,providing the most direct and connected flight feel of any 700-class helicopter.

Every subtle stick movement translates instantly into precise aircraft response,giving pilots a pure, confident, and seamless control experience.

ULTIMATE

TAIL ROTOR SYSTEM

The Specter 700 V2 Ultimate tail system is engineered for maximum precision and stability.

Its all-CNC, one-piece construction enhances alignment accuracy, structural rigidity, and vibration resistance.The system adopts a teeter-style tail rotor design, identical to full-scale helicopter mechanics,delivering superior tail hold, reduced vibration, and quieter operation.Inside the tail rotor hub, curved shim washers with damping O-rings are used to absorb micro-vibrations,providing smoother tail response and improved long-term durability.This refined tail system gives the Specter 700 V2 Ultimate outstanding control precision,combined with the durability and smoothness expected from a true competition-class helicopter

Lower Tail Pushrod Layout

SAFER SHARPER FLIGHT CONTROL

The Specter Ultimate features a lower tail pushrod layout, positioning the tail control linkage beneath the boom.

This design not only improves tail geometry and control precision but also eliminates the safety risk of main blades striking the tail pushrod during extreme 3D maneuvers.The tail servo mount doubles as a belt-tension adjustment system, making setup and maintenance faster and more accurate.

Additionally, the gyro can now be mounted at the rear, resulting in cleaner wiring, better weight balance, and a more responsive, aggressive flight feel.Together, these refinements deliver a perfect balance between mechanical precision, safety, and pure flight performance, showcasing XLPower’s commitment to both engineering excellence and pilot experience.

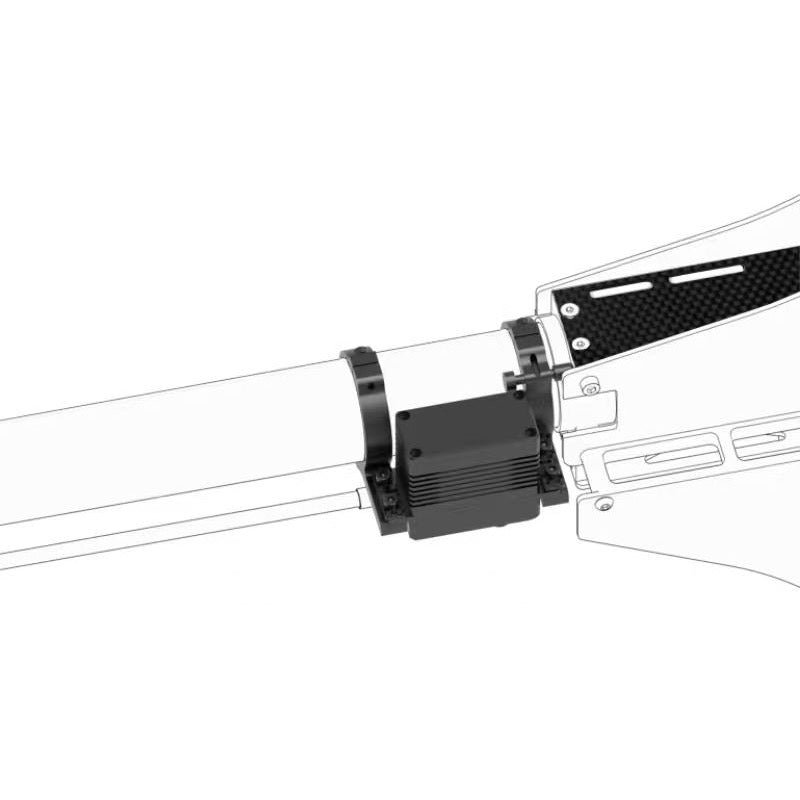

integrated

MOTOR MOUNT AND REINFORCEMENT SYSTEM

The Specter 700 V2 Ultimate features an integrated CNC motor mount that forms the structural backbone of the airframe.

Machined from high-strength aluminum, it directly connects to the central carbon frame reinforcement plate,creating a single, rigid power core that minimizes torsional flex and distributes load evenly through the drivetrain.This reinforced layout enhances structural integrity and reduces resonance across the frame,resulting in crisper power delivery, improved drivetrain efficiency, and a smoother, quieter flight feel.