XLPower

XL55V2K03 - XLPower Nimbus 550 V2

XL55V2K03 - XLPower Nimbus 550 V2

Couldn't load pickup availability

Nimbus 550 V2

Precision · Power · Progress

Overview

The Nimbus 550 V2 builds on XLPower’s proven 550-class platform, engineered for demanding 3D and precision pilots.

Every component—from the strengthened rotor head to the compact upright servo layout—has been refined for smoother response, easier maintenance, and enhanced mechanical efficiency.

With full-size servo support, a new quick-release battery system, and optimized gear ratios, the Nimbus 550 V2 delivers high-power flight in a perfectly balanced mid-size airframe.

Designed for accuracy, durability, and maximum pilot confidence.

Structure Design

The Nimbus 550 V2 introduces XLPower’s innovative upright 120° servo layout, creating a more compact frame with precise, direct control response.

Its rotor head shares the same 1:1 control geometry as the Specter 700 V2, ensuring perfectly linear servo motion, reduced asymmetry, and a more connected, natural flight feel.

The system natively supports four full-size servos, with an optional mid-servo conversion kit available—but full-size servos are strongly recommended for the best performance, durability, and crash resistance.

Its 2.5 mm carbon upper side frames combined with a 7075 aluminum alloy chassis and rotor head deliver outstanding rigidity and crash resilience.

Designed as the strongest and most practical 550-class training helicopter, the Nimbus 550 V2 keeps spare parts affordable and easy to service.

A quick-release canopy system and optional rear battery quick-connect system allow battery swaps in under five seconds—no canopy removal needed.

As one of the lightest 550-class models on the market, it offers excellent 6S compatibility and explosive flight power.

Drive System

The Nimbus 550 V2 features a fully CNC-machined 11 mm main gear built for strength and precision.

A dual one-way bearing hub ensures maximum torque transfer and smooth autorotation performance—eliminating the risk of one-way slippage or failure.

This advanced transmission design provides reliable, consistent power delivery even under extreme 3D loads.

Tail Control System

The Nimbus 550 V2 features a tapered end-fitting design with an aluminum-core carbon tail control rod,

eliminating the need for traditional epoxy bonding for easier, safer, and more precise assembly.

Rod ends can be replaced quickly in the field—no curing time required—so you can be back in the air within minutes.

If damaged, only the carbon rod itself needs replacement, reducing maintenance costs while ensuring consistent tail control precision and long-term reliability.

Additionally, the tail rotor hub shares the same design as the Specter 700 V2,

utilizing a true teetering tail rotor system inspired by full-scale helicopter mechanics.

This configuration allows the tail grips to self-balance under load,

delivering stronger tail hold, lower vibration, and smoother, quieter operation even during aggressive maneuvers.

Key Features

Full-Size Servo Integration

Supports full-size cyclic and tail servos for greater torque handling and precision under load.

1:1 Rotor Head Geometry

Shares the same geometry as the Specter 700 V2, providing perfectly linear, symmetrical, and predictable control response.

Dual One-Way Main Hub

High-grade bearings and dual one-way system ensure efficient torque transfer and reliable autorotation performance.

CNC 7075 Aluminum Rotor Head

Machined to extreme tolerances for maximum rigidity and zero slop—delivering sharp cyclic feedback and solid feel.

Lightweight Carbon-Fiber Frame

Reinforced 2.5 mm side plates and cross bracing provide exceptional torsional strength without excess mass.

Quick-Release Canopy System

Independent latch design allows the canopy to be attached or removed in seconds—making battery swaps and maintenance faster and easier.

Quick-Release Battery System

Bottom-mount tray enables rapid pack changes and easy CG adjustment. Optional rear quick-connect system allows plug-in operation without removing the canopy.

Teetering Tail Rotor Hub

True-scale teeter design for stronger tail hold, lower vibration, and smoother, quieter tail performance.

Simplified Maintenance

Easy access to main gear, servos, and electronics for quick setup, servicing, or upgrades.

Share

TECHNICAL SPECIFICATIONS

Length w/o main blades: 1,180 mm

Overall height: 320 mm

Frame width: 206 mm

Frame weight: 1,480 g

Main shaft diameter: 10 mm

Feathering shaft diameter: 8 mm

Main gear: 106 T

Autorotation pulley: 60 T

Tail pulley: 13 T

Tail ratio: 4.6 : 1

Recommended main blades: 550 – 570 mm

Battery tray size: 290 × 53.5 × 66 mm

Motor class: 4025 – 4035

ESC rating: 100 – 130 A

Servo size: Full-size cyclic and tail

Power system: Electric, 6S – 12S (depending on setup)

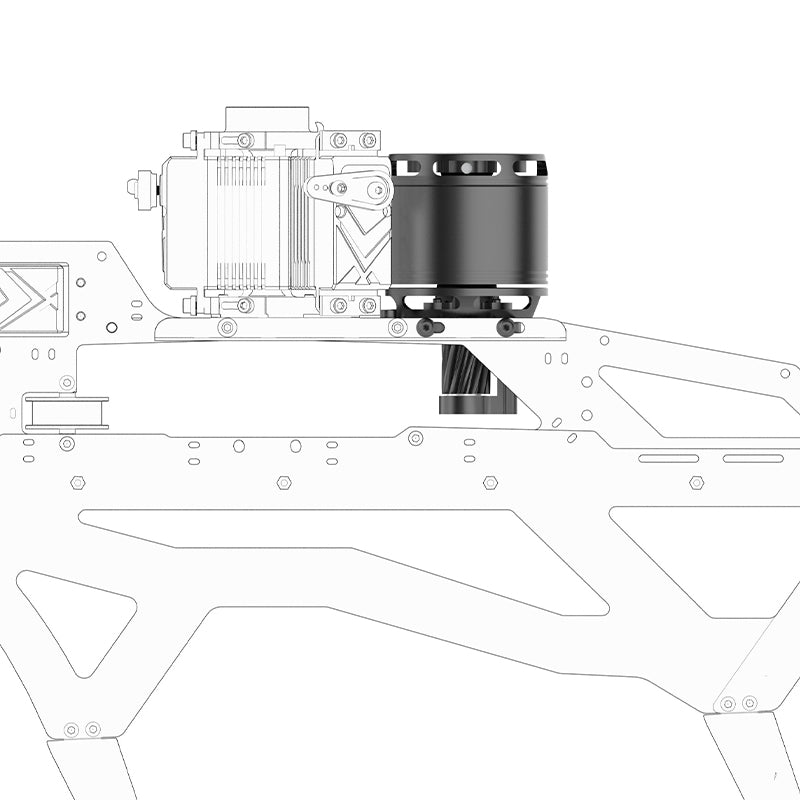

Motor Mount &

CENTER-OF-GRAVITY DESIGN

The motor mount is positioned close to the helicopter’s center of gravity for optimal balance and handling. An integrated support bearing on the pinion stabilizes the motor shaft, ensuring precise gear mesh, reduced vibration, and extended bearing life—essential for high-power electric setups.

SERVO LAYOUT

GEOMETRY

Clean, direct servo placement with optimized linkage geometry delivers mechanical efficiency, equal throw on all axes, and a simplified setup for consistent response throughout the entire flight range. Aone-piece 7075 aluminum bearing block and servo mountform the structural backbone of the frame, providing exceptional drivetrain rigidity and stability even during the most aggressive maneuvers.

Advanced

ROTOR HEAD SYSTEM

Machined from high-strength 7075-grade aluminum, the rigid rotor head provides maximum stability and precise control response. Optimized geometry and high-precision linkage deliver perfectly linear cyclic feedback, while the1:1 control geometryensures equal movement in all directions and a consistent, balanced feel — ideal for both aggressive 3D and precise F3C flight.

Dual one-way precision

FULL CNC STRENGTH

The Nimbus 550 V2 features a fully CNC-machined main gear with an ultra-rigid 11 mm structure for exceptional strength under extreme loads.

Its dual one-way bearing system delivers superior torque capacity and consistent power transfer—eliminating the risk of one-way slippage or failure.

Every climb, every reversal — driven with absolute confidence by a transmission built for performance.

Tail Control

ROD SYSTEM

The carbon tail control rod features a tapered end-fitting design with an aluminum-core shaft.

This patented system eliminates the need for traditional epoxy bonding, making assembly easier, safer, and more precise.

It allows quick field replacement of the rod ends—no more waiting hours for epoxy to cure—so you can get back in the air faster.

In case of damage, the carbon rod itself can also be replaced independently, reducing maintenance cost while maintaining long-term reliability and consistent tail control performance.

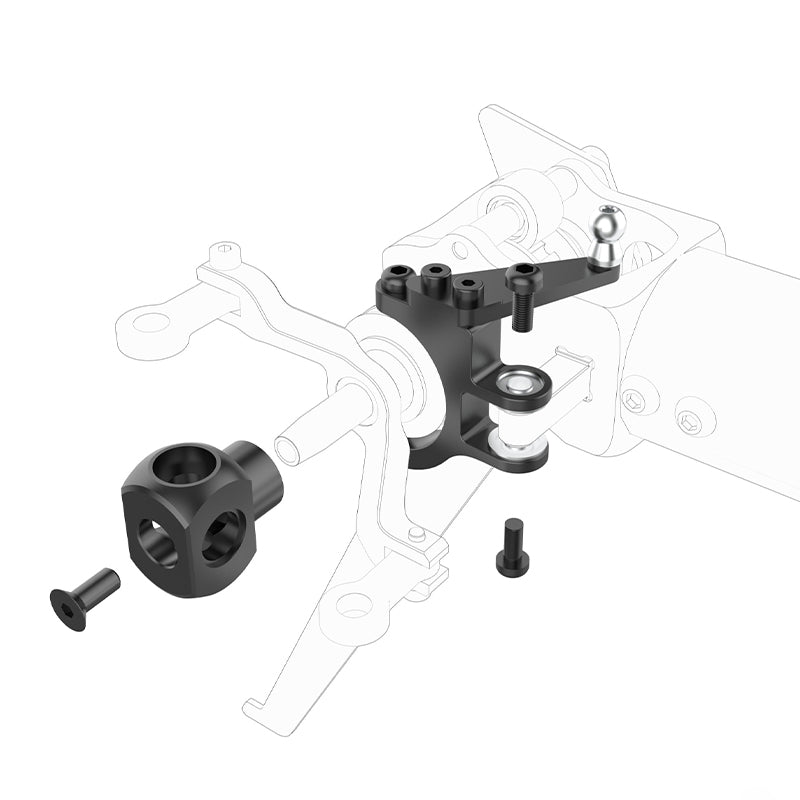

One-Piece

CNC TAIL CASE

A single solid aluminum tail case increases rigidity and ensures perfect gear mesh alignment. The one-piece design improves strength, reduces vibration, and simplifies maintenance compared to multi-part housings.

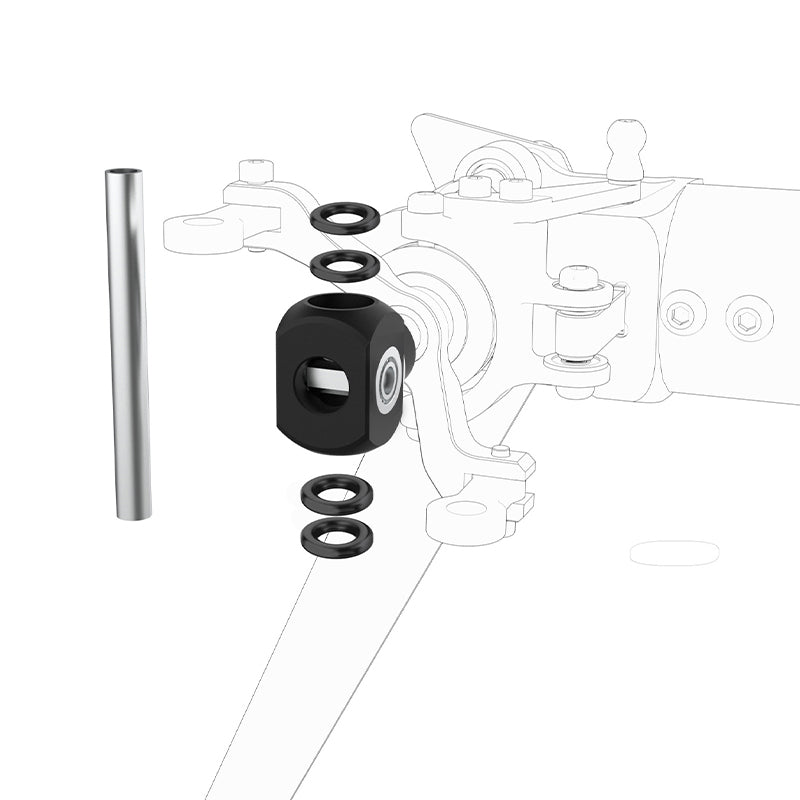

DAMPENING SYSTEM &

TAIL HUB

Precision CNC-machined from aircraft-grade aluminum for exceptional balance and durability. Theteetering tail rotor system, shared with the Nimbus 550 V2 electric version, delivers stronger tail-hold performance, reduced vibration, and improved parts compatibility for easier maintenance and upgrades.

Assembly of the

TAIL HUB

The tail hub uses atapered collet connectionidentical to the Specter 700, effectively reducing vibration and simplifying maintenance — in most crash cases, only the tail shaft needs replacement, costing just a few dollars.