XLPower

XL55NK02 - XLPower Nimbus 550 V2 Nitro

XL55NK02 - XLPower Nimbus 550 V2 Nitro

Couldn't load pickup availability

Nimbus 550 V2 Nitro — Balanced Power, Refined Precision

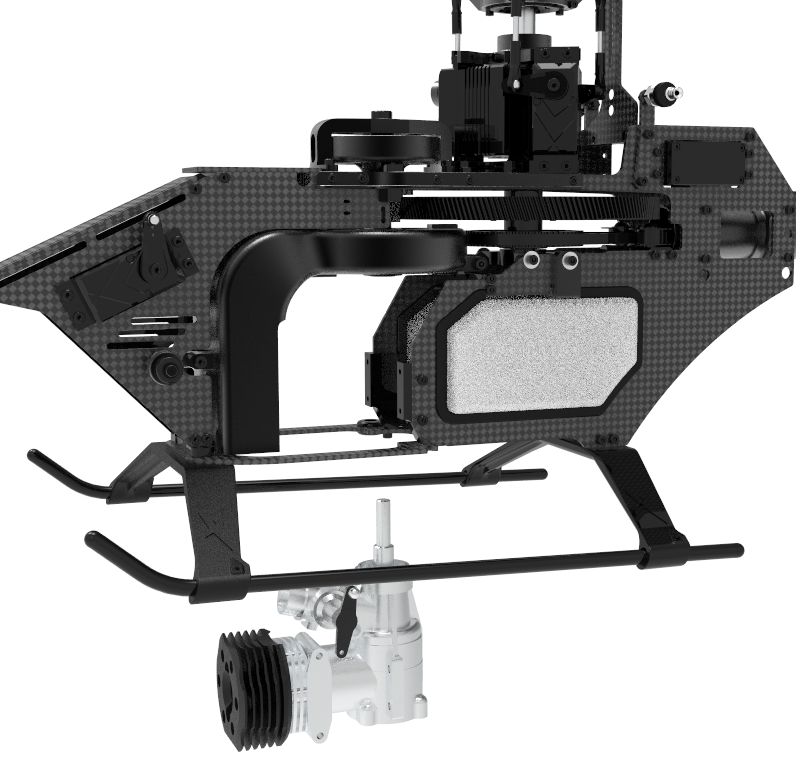

The Nimbus 550 V2 Nitro is XLPower’s next evolution of its high-performance nitro-powered 550-class helicopter kit. Building on the proven foundation of the original Nimbus 550 Nitro, the V2 refines every critical system for greater smoothness, reliability, and control. It combines the precise control geometry of its electric predecessors with a robust, meticulously balanced nitro drivetrain—delivering responsive power, smooth clutch engagement, and exceptional maintainability for advanced pilots.

Key Improvements (V2 vs Original)

🧩 Pre-balanced clutch assembly for reduced vibration and extended bearing life

⚙️ Extended engine shaft for improved axial stability and smoother operation

🔧 Re-engineered start coupling — starter cup no longer sits inside the bearing, preventing clutch loosening during operation

🌀 New tail pitch lever system adopted from the electric V2, offering stronger tail authority and crisper response

💨 Significantly lower vibration across all RPM ranges, with smoother spool-up and more stable hover

Core Features

Redesigned Upper Swash Plate & Geometry

To eliminate unequal cyclic/collective differential, the Nimbus 550 V2 Nitro ships with a new upper swash plate and longer outer swash balls. This refinement ensures balanced servo geometry while maintaining the proven control ratios from the electric Nimbus series.

Tapered Clutch System

Borrowed from the Nitro 700 platform, the tapered clutch provides smoother engagement and easier clutch stack alignment, further enhanced in the V2 with pre-balancing for ultra-low vibration.

Rigid Airframe Core

A one-piece 7075 aluminum bearing block and servo mount form the structural backbone of the frame, giving outstanding drivetrain rigidity and stability during aggressive maneuvers.

120° Cyclic Servo Layout

Servos are arranged in a 120° layout for optimal geometry, ensuring consistent control feel across the full collective range.

Ease of Maintenance

The engine can be removed from the bottom of the frame in minutes without dismantling other assemblies. The fan shroud is independently detachable from the side, simplifying maintenance and tuning.

Balanced Gear Ratio

Standard 7.7:1 gear ratio optimized for 550–580 mm blades, offering excellent RPM and torque balance for demanding maneuvers. Optional 8.5:1 ratio upgrade extends capability to 650-class setups.

Built for pilots who demand the perfect harmony of nitro power and XLPower precision, the Nimbus 550 V2 Nitro delivers confidence you can feel — from start-up to touchdown.

Share

TECHNICAL SPECIFICATIONS

Length w/o main blades: 1,148 mm

Overall height: 315 mm

Frame width: 206 mm

Frame weight: 1,500 g

Main shaft diameter: 10 mm

Feathering shaft diameter: 8 mm

Main gear: 170 T

Pinion gear:22T(20T Optional)

Main gear ratio:7.7(8.5 Optional)

Tail ratio: 4.615 (5 Optional)

Fuel tank capacity: 345 cc

Recommended blade length: 550 – 580 mm

Engine class: .50 – .55 nitro

Power system: Nitro (requires engine, pipe, servos, and gyro)

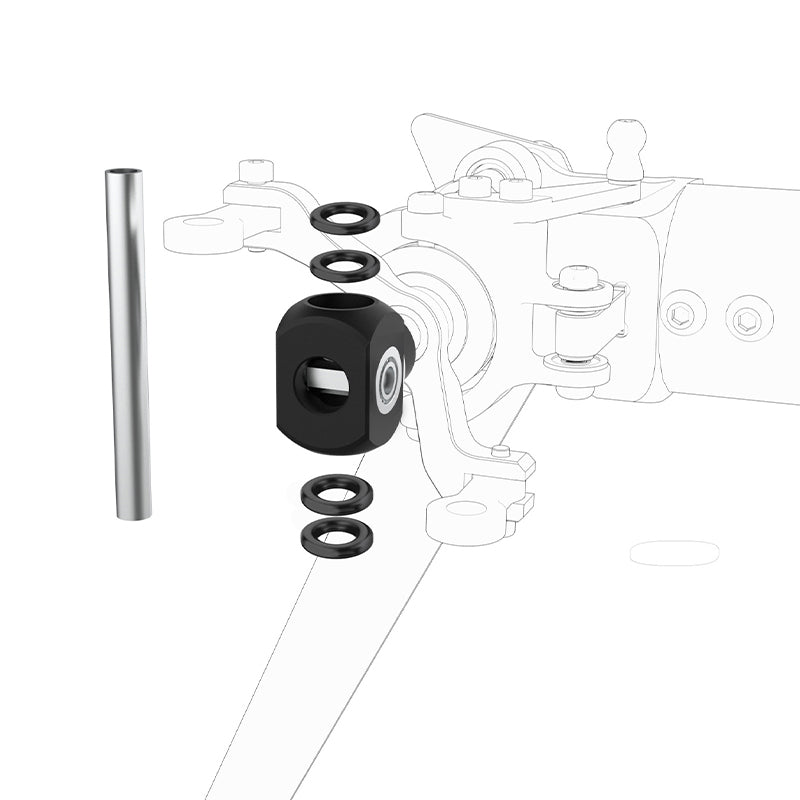

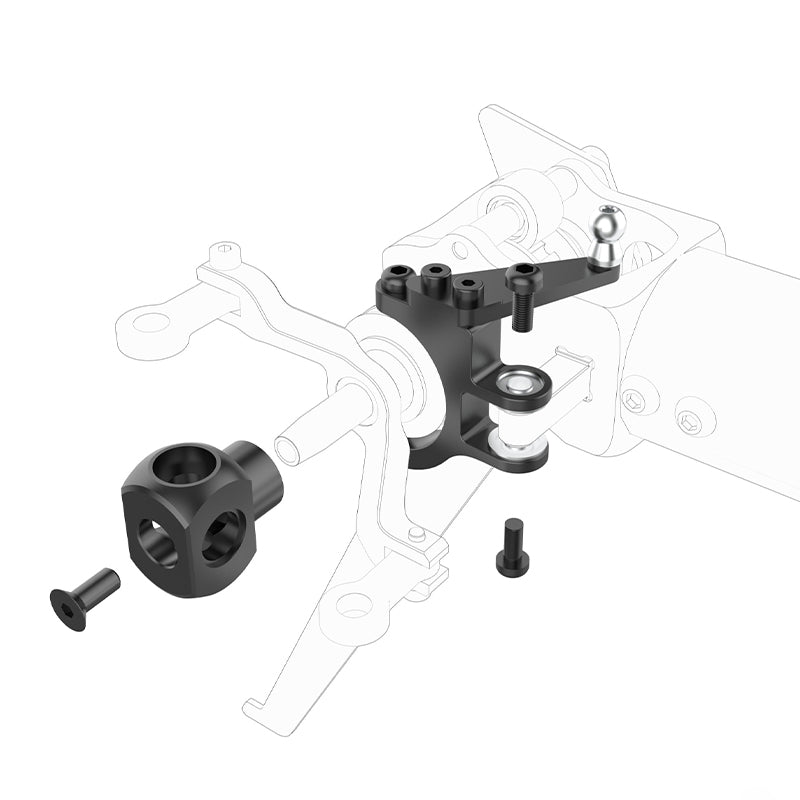

All-New Compact Nitro Clutch System

The new system features multiple engineering upgrades over the previous version:

🧩 All-new pre-balanced clutch assembly — factory balanced to minimize vibration and extend bearing life.

⚙️ Redesigned extended engine shaft — provides higher axial rigidity and smoother transmission, greatly reducing clutch stack distortion under load.

🔧 Refined starter coupling structure — starter cup no longer sits inside the bearing, preventing loosening during operation and improving long-term reliability.

🎯 Improved concentricity — upper clutch bearing alignment has been significantly enhanced for a smoother, more efficient drivetrain.

🧰 Optimized taper angle — allows easier installation and secure clutch engagement without excessive tightening.

🔄 Universal compatibility — fully compatible with both OS and YS engines, requiring no modification.

⚖️ Recommended tightening torque — 16–18 Nm for optimal locking force and reliability.

Together, these upgrades result in a drivetrain that runs quieter, stays cooler, and offers unmatched precision and durability — a true step forward from the original Nimbus 550 Nitro.

Precision

CNC MAIN GEAR ASSEMBLY

With a 7.7 gear ratio, it is perfectly matched to achieve a good rotor RPM while providing enough torque for demanding maneuvers with 550–580mm blades. Optional parts are available to stretch it to a 650-size with an 8.5 gear ratio.

The main gear directly drives the head and has been designed to efficiently transmit rotor torque, producing peak power through extreme rigidity.

Advanced

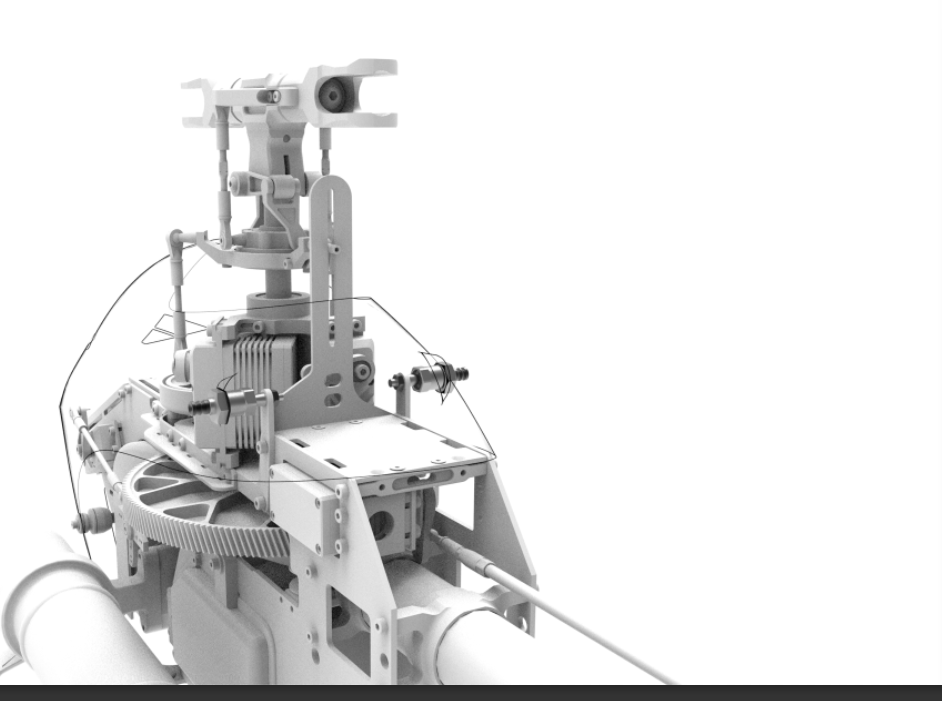

ROTOR HEAD SYSTEM

Machined from high-strength 7075-grade aluminum, the rigid rotor head provides maximum stability and precise control response. Optimized geometry and high-precision linkage deliver perfectly linear cyclic feedback, while the 1:1 control geometry ensures equal movement in all directions and a consistent, balanced feel — ideal for both aggressive 3D and precise F3C flight.

Modular Structure for

EASY MAINTENANCE

Engine maintenance is also easy, with the ability to remove the engine from the bottom without disturbing other assemblies in a matter of minutes. The engine cooling fan shroud can be independently removed by side and without disassembly of other parts.

Quick-Connect Canopy Lock System

Easy connect canopy locks removing the need for safety pins with a much easier way to remove and mount the canopy.

DAMPENING SYSTEM &

TAIL HUB

Precision CNC-machined from aircraft-grade aluminum for exceptional balance and durability. The teetering tail rotor system, shared with the Nimbus 550 V2 electric version, delivers stronger tail-hold performance, reduced vibration, and improved parts compatibility for easier maintenance and upgrades.

Assembly of the

TAIL HUB

The tail hub uses a tapered collet connection identical to the Specter 700, effectively reducing vibration and simplifying maintenance — in most crash cases, only the tail shaft needs replacement, costing just a few dollars.

servo layout

GEOMETRY

Clean, direct servo placement with optimized linkage geometry delivers mechanical efficiency, equal throw on all axes, and a simplified setup for consistent response throughout the entire flight range. A one-piece 7075 aluminum bearing block and servo mount form the structural backbone of the frame, providing exceptional drivetrain rigidity and stability even during the most aggressive maneuvers.