XLPower

XL70V2K06 - XLPower Specter 700V2 ultimate

XL70V2K06 - XLPower Specter 700V2 ultimate

Couldn't load pickup availability

Specter 700 V2 Ultimate

Precision Perfected · Champion Proven

Overview

The evolution continues.

The Specter 700 V2 Ultimate represents the pinnacle of XLPower’s engineering — built for pilots who demand the absolute best in precision, strength, and control.

Based on the proven World Champion Edition platform, every detail of the Ultimate has been enhanced to deliver tighter tolerances, greater rigidity, and smoother flight performance.

With its refreshed canopy design featuring a pure-white tail boom, fin, and landing gear, the Ultimate blends clean aesthetics with refined engineering.

From the one-piece motor mount to the optimized tail geometry, every update reflects XLPower’s ongoing pursuit of perfection through real-world competition and pilot feedback.

Trusted and proven by world-class pilots such as MinChan Kim, Kenny Ko, and Kan Poonnoi,

the Specter 700 V2 Ultimate isn’t just an evolution — it’s the benchmark for what a modern 700-class helicopter can be.

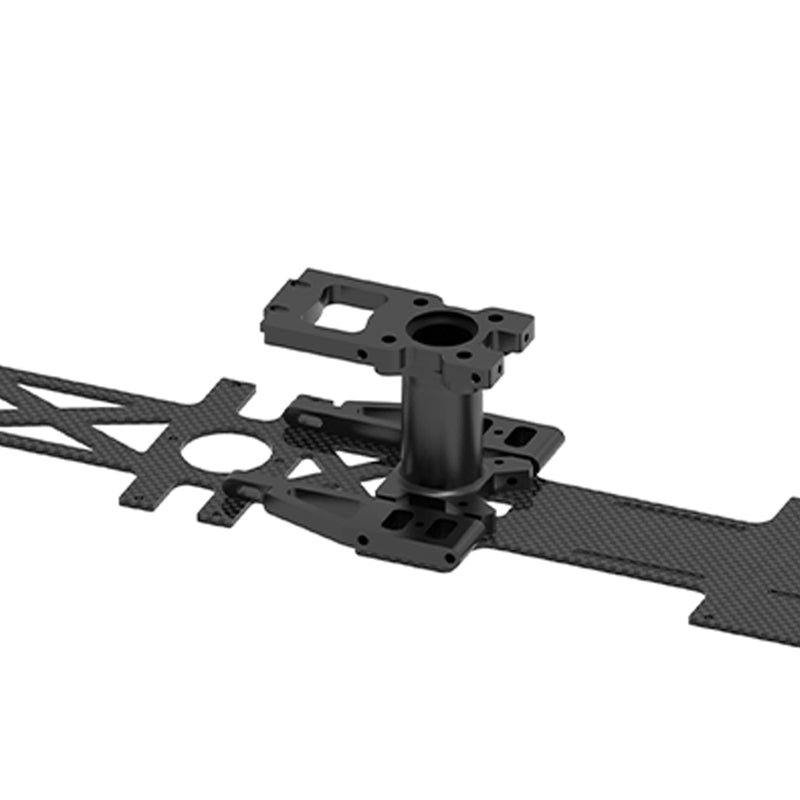

Structure & Design

The Specter 700 V2 Ultimate refines every aspect of the V2 platform for even greater precision and reliability.

A one-piece reinforced motor mount is fully integrated into the main frame, strengthening the powertrain and minimizing torsional flex under high load.

The center and lower frame sections have been reinforced for improved rigidity, maintaining structural accuracy and energy transfer during aggressive flight maneuvers — while retaining XLPower’s hallmark lightness and service-friendly layout.

The lower tail-servo placement is not merely for linkage optimization — it’s a safety-driven refinement inspired by feedback from world-champion pilots performing extreme 3D maneuvers.

This new layout effectively prevents main-blade–to–tail-control-rod interference (blade-to-tail-rod strike) during large tail deflections and extreme attitudes, ensuring structural safety and consistency under the harshest flight conditions.

The rotor head assembly continues XLPower’s iconic 1:1 geometry design,

renowned by top-level pilots as one of the best-feeling 700-class systems ever made.

Each component is fully CNC-machined in a single setup, ensuring ultra-tight tolerances and perfect concentricity.

This precision allows every subtle stick input to translate instantly into clean, linear aircraft response — delivering an unmatched, connected flight feel.

Both the main rotor head and tail rotor assemblies are crafted from 7075-T6 aerospace-grade aluminum, precision CNC-machined for maximum strength, rigidity, and fatigue resistance.

This material choice provides exceptional stability under extreme torque and high-RPM conditions, while keeping the overall weight optimized for agility and responsiveness.

Performance & Flight Feel

The Ultimate’s frame dynamics are engineered for maximum control fidelity.

Its improved stiffness delivers a solid, locked-in feel during high-stress maneuvers without compromising agility.

The result is a model that tracks like it’s on rails — precise, predictable, and confidence-inspiring — even in the most demanding 3D or competition routines.

Paired with XLPower’s signature drivetrain smoothness and refined damping system,

the Specter 700 V2 Ultimate gives pilots an unmistakable sense of balance, authority, and flight connection that defines the XLPower experience.

Key Features

One-Piece Reinforced Motor Mount

Integrated directly into the frame for stronger load paths and reduced torsional flex.

Strengthened Center & Lower Frame Sections

Improved chassis rigidity for consistent geometry and efficient power transfer under load.

Lower Tail Servo Placement

A safety-oriented design that prevents main-blade–to–tail-control-rod interference during extreme flight.

1:1 Rotor Head Geometry

Proven Specter design for perfectly linear control response and exceptional pilot feel.

Fully CNC-Machined 7075 Rotor Head & Tail Assemblies

Aerospace-grade aluminum, single-setup machining, ultra-tight tolerances — strength, precision, and responsiveness in perfect harmony.

Curved Dampening Washers & Gearbox Shims

Reduce vibration, improve tail precision, and increase long-term durability.

Rear-Mounted Gyro Plate

Enhanced vibration isolation for cleaner gyro signals and smoother flybarless control.

Quick-Release Canopy System

Standard feature — tool-free latch design allows canopy installation or removal in seconds for fast field access and battery changes.

Optional Quick-Connect Battery System

Available rear-entry battery connection allows rapid plug-in power changes without removing the canopy.

Refined Canopy & Aesthetic Details

White tail boom, fin, and landing gear deliver a clean, modern look that reflects engineering excellence.

Competition-Proven Design

Tested and trusted by world-class pilots for top-tier reliability and performance.

Share

TECHNICAL SPECIFICATIONS

Length w/o main blades: 1,383 mm

Overall height: 351 mm

Frame width: 217mm

Weight (RTF): approx. 5,400 g

Main blade length: 685 – 720 mm

Tail blade length: 105 – 115 mm

Main shaft diameter: 15 mm

Feathering shaft diameter: 10 mm

Tail boom diameter: 32 mm

Tail ratio: 4.76 : 1(5.0Optional)

Drive system: Belt-driven tail, helical main gear

Gear ratio: 9.63 : 1(8.15-11.77 Optional)

Motor mount: One-piece reinforced CNC aluminum design

Frame structure: Multi-layer carbon fiber with strengthened center section

Swashplate geometry: 120° CCPM, 1:1 control ratio

Power system: 12S Li-Po (recommended)

ESC rating: 130 – 260 A class

Motor class: 4525 / 4530 size

Head & tail material: 7075-T6 aluminum

Gyro mount: Rear-mounted vibration-isolated platform

Battery tray: Quick-release latch system

The Heart of

ULTIMATE CONTROL

The Specter 700 V2 Ultimate rotor head represents the pinnacle of precision engineering and flight refinement.

Each component is fully CNC-machined from 7075-T6 aerospace-grade aluminum in a single setup,ensuring exceptional accuracy, rigidity, and near-zero tolerance deviation.

This advanced design delivers unmatched stiffness, perfect tracking, and ultra-smooth control response,even under the extreme dynamic loads of modern 3D flight.

The 1:1 swash-to-rotor geometry guarantees completely linear cyclic and collective behavior,providing the most direct and connected flight feel of any 700-class helicopter.

Every subtle stick movement translates instantly into precise aircraft response,giving pilots a pure, confident, and seamless control experience.

ULTIMATE

TAIL ROTOR SYSTEM

The Specter 700 V2 Ultimate tail system is engineered for maximum precision and stability.

Its all-CNC, one-piece construction enhances alignment accuracy, structural rigidity, and vibration resistance.The system adopts a teeter-style tail rotor design, identical to full-scale helicopter mechanics,delivering superior tail hold, reduced vibration, and quieter operation.Inside the tail rotor hub, curved shim washers with damping O-rings are used to absorb micro-vibrations,providing smoother tail response and improved long-term durability.This refined tail system gives the Specter 700 V2 Ultimate outstanding control precision,combined with the durability and smoothness expected from a true competition-class helicopter

Lower Tail Pushrod Layout

SAFER SHARPER FLIGHT CONTROL

The Specter Ultimate features a lower tail pushrod layout, positioning the tail control linkage beneath the boom.

This design not only improves tail geometry and control precision but also eliminates the safety risk of main blades striking the tail pushrod during extreme 3D maneuvers.The tail servo mount doubles as a belt-tension adjustment system, making setup and maintenance faster and more accurate.

Additionally, the gyro can now be mounted at the rear, resulting in cleaner wiring, better weight balance, and a more responsive, aggressive flight feel.Together, these refinements deliver a perfect balance between mechanical precision, safety, and pure flight performance, showcasing XLPower’s commitment to both engineering excellence and pilot experience.

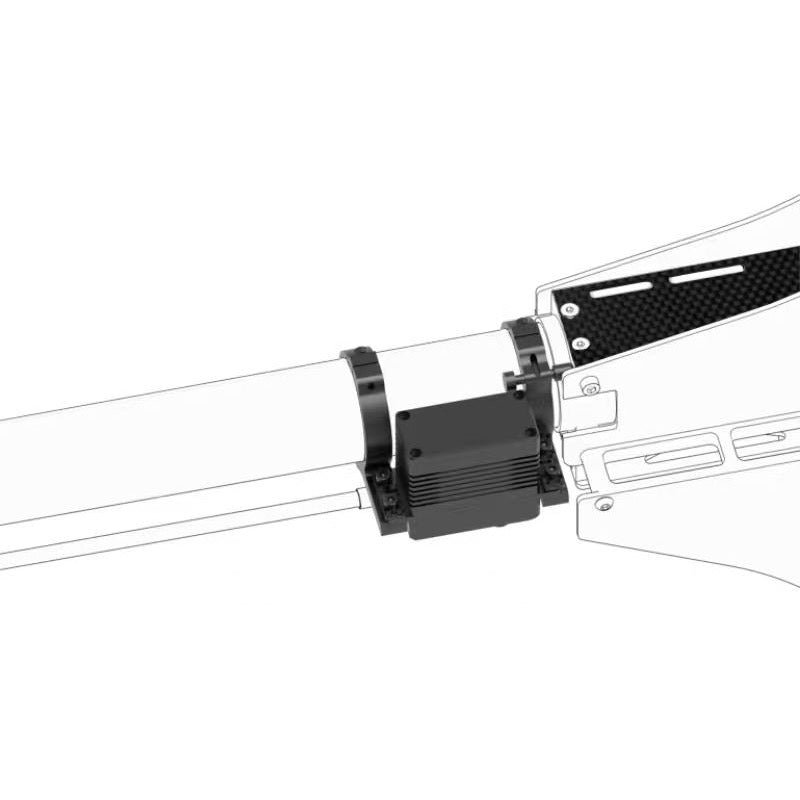

integrated

MOTOR MOUNT AND REINFORCEMENT SYSTEM

The Specter 700 V2 Ultimate features an integrated CNC motor mount that forms the structural backbone of the airframe.

Machined from high-strength aluminum, it directly connects to the central carbon frame reinforcement plate,creating a single, rigid power core that minimizes torsional flex and distributes load evenly through the drivetrain.This reinforced layout enhances structural integrity and reduces resonance across the frame,resulting in crisper power delivery, improved drivetrain efficiency, and a smoother, quieter flight feel.